A Production Infrastructure to Meet Diverse Needs

In order to deliver safe and high-quality products to our customers, our facilities conform to both ISO9001 and FSSC22000 specifications.

Since 2014, we have engaged in the N.S.P.I. (Next Shiono Producing Innovation), a series of reforms for better manufacturing that are shrinking lead time from order through fulfillment. This initiative is also training “multi-skilled workers” who can master a range of tasks. This allows us to install a manufacturing personnel structure with members who can flexibly adapt to the priorities of each day.

-

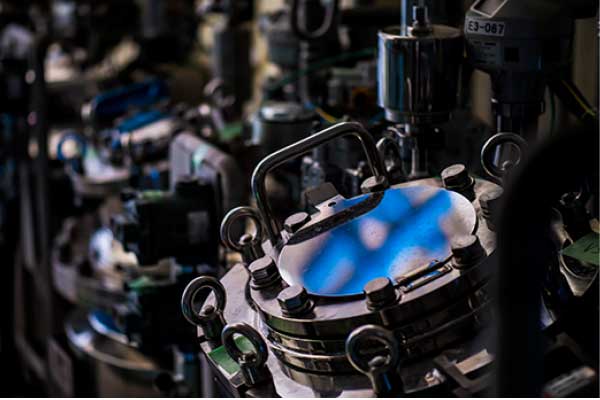

Proprietary equipment

We have incorporated proprietary solutions to the processes of chemical reactions, separation, and enrichment, creating a specialty materials production flow.

-

High-quality extraction

We employ the latest equipment and facilities to enhance and automate our proprietary extraction process. This enables us to achieve a workflow whereby we can produce a stable and high-quality supply of products.

-

A flexible production scheme using multi-skilled workers

We train personnel who have a wide range of skills, allowing a single member to handle a variety of processes. This has enabled us to create a flexible production structure with talent poised to meet emergent challenges.

Advanced Production Technology

Shiono Koryo, seeking to prevent human error and reduce the workload of our personnel, has employed refinements such as a weight system which digitizes paper order forms and a production management system that gives a visual readout of orders spanning the initial order through shipment process. The latter lets us take a data-driven approach to our inventory and achieve more advanced production plans. Products are stored in facilities like our Automatic Hazard Inventory System and Automatic Refrigeration Inventory System, which are equipped with the latest earthquake-resistant design and temperature controls. Integration with our production management system allows for the smooth visualization of incoming and outgoing inventory.

-

Weight systems prevent human error

We have employed a paperless weight system and double-checking structure. Weight is digitally displayed; zeroing it prevents for the accidental insertion of material.

-

Production management systems that let us visualize the workflow

We have employed a production management system that lets us get a visual readout of the entire workflow, from order through delivery. Managing data on raw materials inventory lets us achieve a higher fidelity of production plans.

-

Efficient inventory management tied to our production system

Automatic Hazard Inventory System and Automatic Refrigeration Inventory System employ the latest earthquake-resistant structure and temperature controls. Integration with our production management system allows for the smooth visualization of incoming and outgoing inventory.